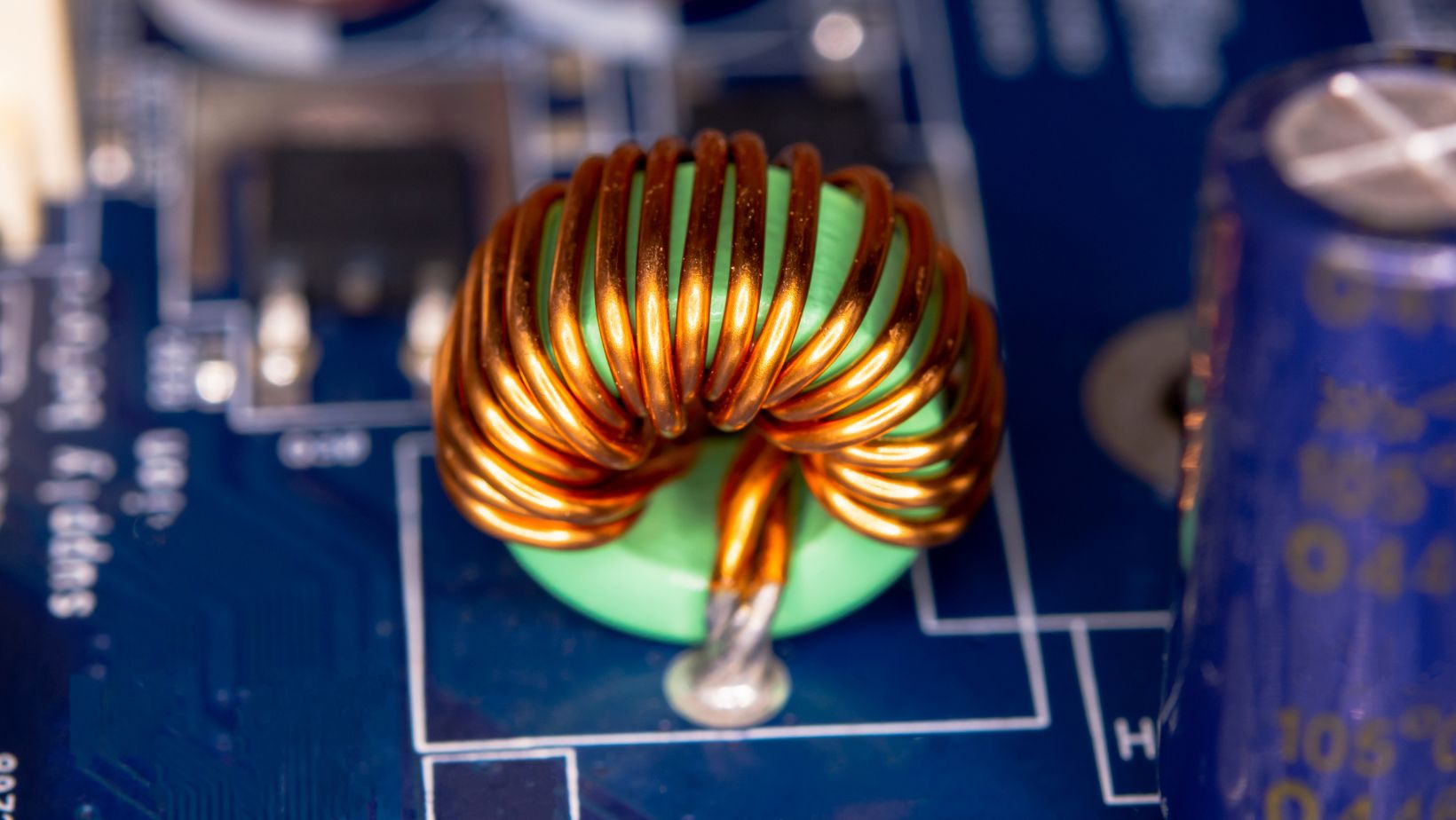

In the world of electromagnetic devices, micro coils represent a great technical development. Designed by coining an electrical conductor into a small shape, these tiny coils have great uses in many fields, especially in medicine. Their modest size lets them work well in settings where conventional coils would be too big or heavy. The main characteristics of micro coils come into the spotlight in this article along with their exciting future.

Key Features of Micro Coils

1. Precision Engineering

Designed to fulfill certain criteria like inductance, resistance, and magnetic field intensity, micro coils are Their size may be adjusted to match precise requirements; often, handling and inspection need for the employment of magnifying tools. Applications with restriction of space and accuracy are of great importance depending on this precision.

2. Miniaturization Challenges

As the demand for miniaturized medical devices increases, designers face the challenge of creating components that fit within tight physical constraints. Micro coils can be smaller than traditional coils, fitting within the eye of a needle, making them ideal for invasive medical devices. This miniaturization is essential for developing cutting-edge micro-motion control and positioning systems that cater to modern medical needs.

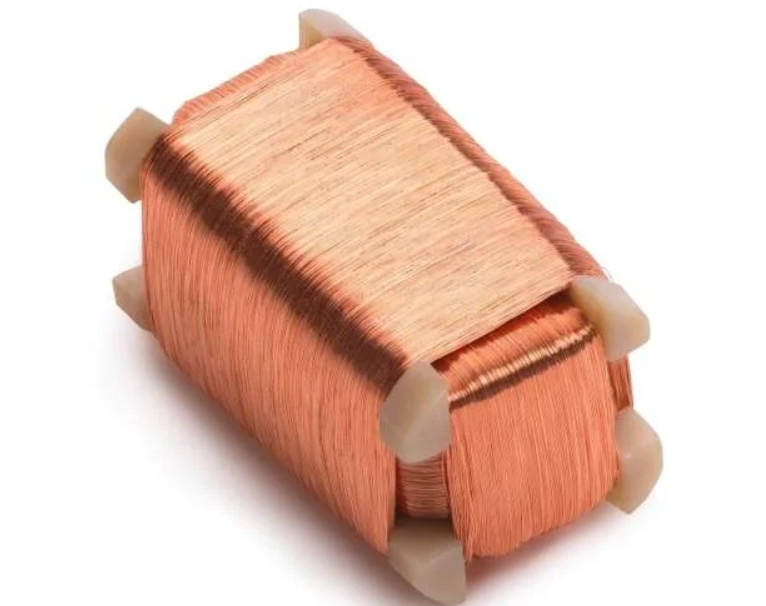

3. Use of Ultra-Fine Wires

Usually using ultra-fine wires—which may be as thin as eight microns in diameter—micro coil production calls for The difficulties of twisting and joining these fragile wires call for creative production techniques.

Development of techniques and specialized equipment create these coils while preserving high performance and quality requirements.

4. Innovative Connectivity Solutions

The connection of ultra-fine wires is a major obstacle in micro coil manufacturing. Reliable, corrosion-resistant, and strain-free connections produced by use of creative thermo-pressure bonding technology come in play. Thanks to this development, premium micro coils fit for both disposable and long-lasting medical equipment may be produced.

5. Industrial Production Capabilities

Micro coils may now be manufactured in industrial numbers because of developments in manufacturing technology, fulfilling the strict criteria of many uses—especially in the medical field.

This capacity guarantees that premium components are easily accessible for use in important medical equipment, therefore improving patient care and results.

The Future of Micro Coil and Ultra-Fine Wire Technologies

Micro coils and ultra-fine wire technologies have bright futures especially as the market for medical device downsizing increases. Micro coils become more and more important as designers work to construct tools that can negotiate high-density body parts without interfering with routine activities.

Furthermore, developments in micro coil technologies will probably result in extended lifetime for implanted components and improved energy economy. The capacity to mass-produ reasonably priced, high-quality, small components will provide fresh opportunities for creativity in the medical and other sectors.

Micro coils are becoming more and more important instruments in the creation of modern medical devices and beyond as more designers see their benefits. Their uses should grow. Micro coil technology’s ongoing investment will propel more performance, dependability, and functionality enhancements, thus guaranteeing that these little components have a major influence on the direction of technology and healthcare.