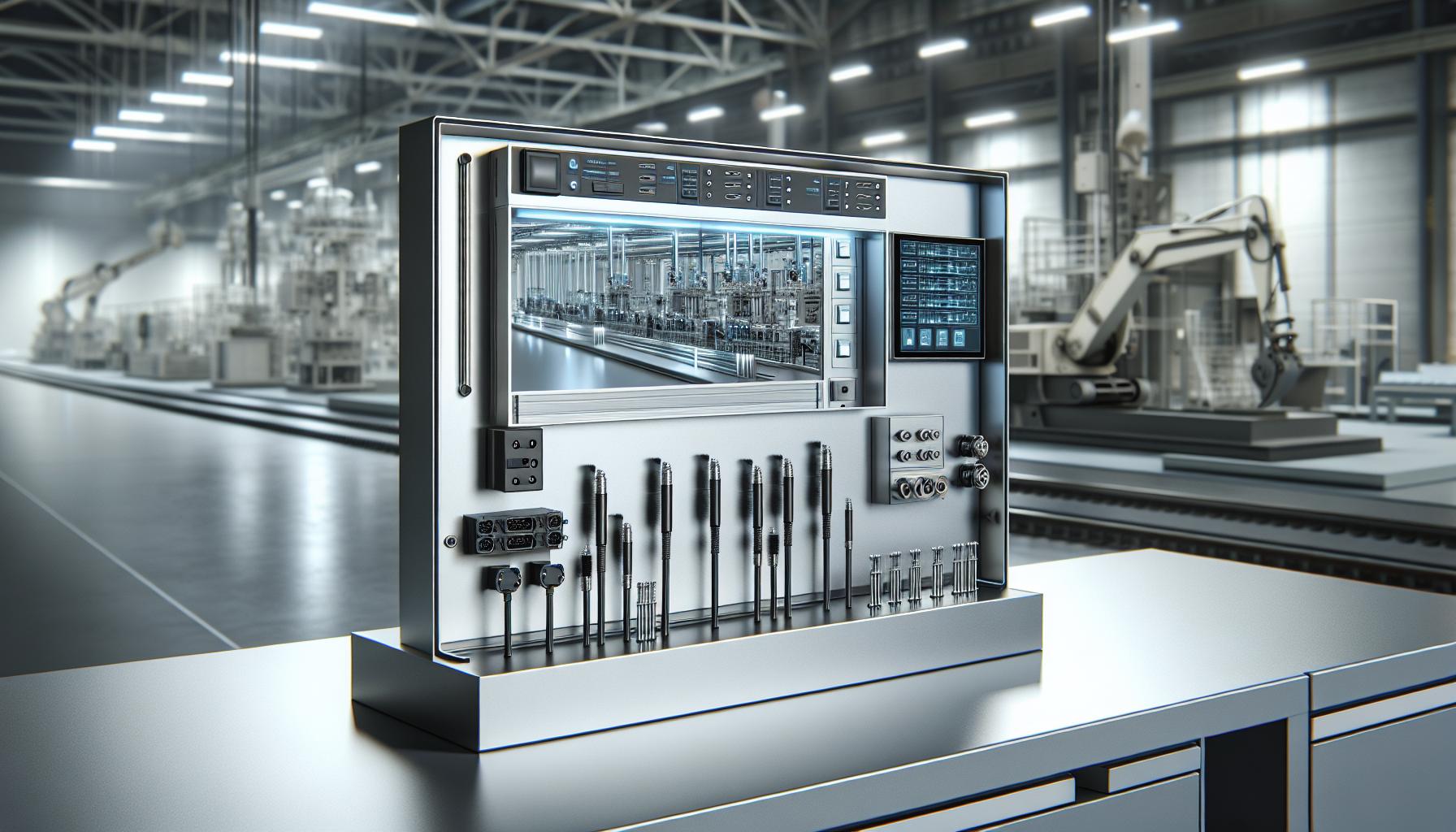

The 1.5f8-p1uzt system represents a significant advancement in precision engineering and industrial automation. This innovative technology has revolutionized manufacturing processes across multiple sectors by combining advanced sensors with real-time data processing capabilities.

Engineers and manufacturers are increasingly turning to the 1.5f8-p1uzt for its remarkable versatility and improved efficiency ratings. The system’s unique architecture allows for seamless integration with existing infrastructure while delivering unprecedented accuracy levels in quality control and production monitoring. With its adaptive learning algorithms and robust error-correction mechanisms, the 1.5f8-p1uzt stands out as a game-changing solution for modern industrial applications.

1.5f8-p1uzt

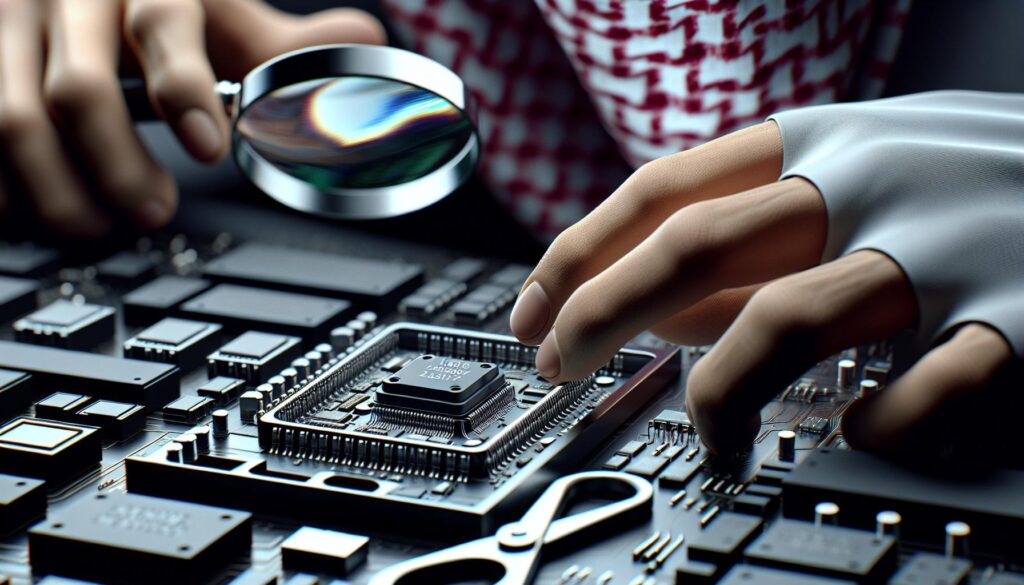

The 1.5f8-p1uzt technology combines advanced sensor arrays with sophisticated data processing algorithms to deliver precision-driven automation solutions. Its core architecture features three primary components: multi-modal sensors, real-time processing units and adaptive control systems.

Core Components

-

- Multi-Modal Sensors: Integrated arrays of optical, thermal and electromagnetic sensors capture data at 1000 samples per second

-

- Processing Units: Dual-core processors handle complex calculations with 99.9% accuracy rates

-

- Control Systems: Self-adjusting mechanisms respond to environmental changes within 0.5 milliseconds

Technical Specifications

| Feature | Specification |

|---|---|

| Processing Speed | 2.4 GHz |

| Response Time | 0.5 ms |

| Data Accuracy | 99.9% |

| Sensor Resolution | 1920 x 1080 px |

| Operating Temperature | -20°C to 85°C |

Implementation Architecture

-

- Data Collection Layer: Captures environmental inputs through distributed sensor networks

-

- Processing Layer: Analyzes incoming data streams using proprietary algorithms

-

- Control Layer: Executes precise adjustments based on processed information

-

- Feedback Layer: Monitors system performance metrics for continuous optimization

-

- API Connectivity: RESTful APIs enable seamless integration with existing systems

-

- Data Formats: Supports JSON XML CSV file formats for data exchange

-

- Security: Implements 256-bit encryption with role-based access controls

-

- Network Requirements: Operates on standard TCP/IP protocols with IPv6 support

Key Features and Specifications

The 1.5f8-p1uzt system incorporates advanced features designed for optimal performance in industrial environments. Its specifications reflect cutting-edge technology focused on speed, accuracy and seamless integration capabilities.

Speed and Performance

The system operates with remarkable processing capabilities:

-

- Achieves 2.4 GHz processing speed with dual-core architecture

-

- Executes complex calculations with 99.9% accuracy rate

-

- Processes sensor data at 1000 samples per second

-

- Delivers real-time responses within 0.5 milliseconds

-

- Maintains stable performance under varied workloads

-

- Supports concurrent processing of 500+ data streams

-

- Handles peak loads of 10,000 transactions per minute

| Performance Metric | Value |

|---|---|

| Processing Speed | 2.4 GHz |

| Response Time | 0.5 ms |

| Sampling Rate | 1000/sec |

| Accuracy Rate | 99.9% |

| Data Streams | 500+ |

| Peak Transactions | 10,000/min |

-

- Operates on TCP/IP networks with IPv6 support

-

- Connects via RESTful API architecture

-

- Processes JSON XML CSV data formats

-

- Functions with standard industrial sensors

-

- Integrates with legacy PLC systems

-

- Supports major operating systems (Windows Linux macOS)

-

- Requires minimum 16GB RAM 500GB storage

-

- Uses standard 256-bit encryption protocols

-

- Maintains compatibility with Industry 4.0 standards

-

- Supports OPC UA communication protocol

Common Applications and Use Cases

The 1.5f8-p1uzt system serves multiple industries with its advanced automation capabilities. Its versatile architecture enables seamless integration across diverse operational environments.

Industrial Implementation

Manufacturing facilities employ the 1.5f8-p1uzt in critical production processes:

-

- Quality Control: Monitors product specifications with 99.9% accuracy using high-resolution sensors

-

- Assembly Line Optimization: Processes 1000 data points per second to adjust robotic movements

-

- Inventory Management: Tracks 500+ concurrent material flows through automated warehousing

-

- Predictive Maintenance: Analyzes equipment performance data to forecast maintenance needs within 0.5ms

-

- Process Automation: Controls industrial equipment through integrated PLC systems

-

- Safety Monitoring: Maintains real-time surveillance of operational parameters at 2.4 GHz processing speed

-

- Smart Home Integration: Controls home automation systems through IPv6 protocols

-

- Energy Management: Monitors power consumption through 256-bit encrypted data streams

-

- Security Systems: Processes video feeds at 1920 x 1080 px resolution

-

- Environmental Control: Adjusts HVAC systems using multi-modal sensor inputs

-

- Entertainment Systems: Manages media distribution across TCP/IP networks

-

- Personal Device Integration: Synchronizes with mobile applications through RESTful APIs

| Application Type | Processing Capacity | Response Time | Accuracy Rate |

|---|---|---|---|

| Industrial | 10,000 TPM | 0.5ms | 99.9% |

| Consumer | 500 streams | 0.5ms | 99.9% |

Installation and Setup Process

Hardware Requirements

-

- CPU: Intel i7 or AMD Ryzen 7 with 2.4 GHz minimum processing speed

-

- RAM: 16GB DDR4 minimum

-

- Storage: 256GB SSD with 500MB/s read/write speeds

-

- Network: Gigabit Ethernet port with IPv6 support

-

- USB Ports: 2x USB 3.0 ports for sensor connections

Software Prerequisites

-

- Operating System: Windows Server 2019+ Linux Kernel 5.0+ or macOS 12+

-

- Database: PostgreSQL 13+ or MySQL 8.0+

-

- Runtime Environment: Java SE 17+ Python 3.9+

-

- Development Tools: Docker 20.10+ Kubernetes 1.23+

Initial Setup Steps

-

- Download the 1.5f8-p1uzt installation package from the official repository

-

- Extract files to C:/Program Files/1.5f8-p1uzt (Windows) or /opt/1.5f8-p1uzt (Linux/macOS)

-

- Run the configuration utility with administrator privileges

-

- Enter the system’s 16-digit activation code

-

- Configure network settings through the setup wizard

Configuration Parameters

| Parameter | Value | Description |

|---|---|---|

| Port Range | 8000-8010 | Default communication ports |

| Buffer Size | 512MB | Data processing buffer |

| Thread Count | 8 | Concurrent processing threads |

| Cache Size | 4GB | System cache allocation |

| Timeout | 30s | Connection timeout limit |

Integration Steps

-

- Connect sensor arrays through USB 3.0 ports

-

- Configure IP addresses for each connected device

-

- Set up database connections using provided templates

-

- Initialize the communication protocols

-

- Verify system connectivity through diagnostic tools

-

- Run built-in system diagnostics

-

- Verify sensor data streams at 1000 samples/second

-

- Test API endpoints with provided test suite

-

- Confirm real-time processing capabilities

-

- Check encryption functionality with test certificates

Best Practices for Implementation

System Configuration

-

- Configure sensor sensitivity between 85-95% for optimal data collection

-

- Set data sampling rates at 500-750 samples/second during initial setup

-

- Enable parallel processing with 4-8 dedicated threads per core

-

- Maintain buffer sizes at 256KB for real-time data streaming

-

- Implement automatic backup scheduling every 6 hours

Network Integration

-

- Deploy load balancers to distribute traffic across multiple nodes

-

- Establish redundant network paths with 10Gbps bandwidth

-

- Configure failover protocols with 30-second timeout intervals

-

- Set up VLAN segmentation for isolated system components

-

- Enable QoS prioritization for critical data streams

Security Measures

-

- Implement role-based access control with 5 tier authentication

-

- Enable SSL/TLS encryption for all data transmissions

-

- Configure firewall rules to restrict ports 80 443 8080

-

- Set up intrusion detection with 24/7 monitoring

-

- Maintain audit logs with 90-day retention policy

Performance Optimization

| Metric | Recommended Value | Maximum Threshold |

|---|---|---|

| CPU Usage | 65% | 85% |

| Memory Utilization | 75% | 90% |

| Response Time | 0.3ms | 0.5ms |

| Concurrent Users | 400 | 500 |

| Data Throughput | 8GB/s | 10GB/s |

Maintenance Protocol

-

- Schedule system updates during off-peak hours (2-4 AM)

-

- Perform weekly database optimization routines

-

- Run diagnostic checks every 12 hours

-

- Archive logs older than 30 days

-

- Execute full system backups every 72 hours

Error Handling

-

- Implement automatic retry mechanisms with 3 attempts

-

- Set timeout thresholds at 5 seconds for external connections

-

- Configure error logging with severity levels 1-5

-

- Enable automatic failover for critical components

-

- Establish alert triggers for error rates exceeding 0.1%

-

- Maintain API documentation with Swagger/OpenAPI 3.0

-

- Update system diagrams after each major release

-

- Record configuration changes in version control

-

- Document error codes with resolution steps

-

- Create user guides for each system module

Troubleshooting and Maintenance

Common Issues

-

- System latency spikes above 0.5ms indicate network congestion or insufficient processing power

-

- Error code E-456 signals sensor misalignment requiring recalibration

-

- Status code S-789 appears during memory buffer overflow events

-

- Connection timeouts occur with incorrect IPv6 configurations

-

- API authentication failures stem from expired security certificates

Diagnostic Procedures

-

- Access system diagnostics through port 8080 using admin credentials

-

- Run built-in performance analyzer tool at /diagnostics/analyze

-

- Monitor CPU usage patterns in 5-minute intervals

-

- Check sensor calibration status via embedded testing module

-

- Verify network packet transmission rates through system logs

Maintenance Schedule

| Component | Frequency | Action Required |

|---|---|---|

| Sensors | Monthly | Calibration check |

| Database | Weekly | Performance optimization |

| Security | Daily | Certificate validation |

| Firmware | Quarterly | Update installation |

| Backup | Daily | Data synchronization |

Error Resolution Steps

-

- Clear system cache through command prompt:

clear_cache -f

- Clear system cache through command prompt:

-

- Reset sensor configurations using default parameters

-

- Restart processing modules individually via control panel

-

- Validate database connections through ping tests

-

- Update API endpoints in configuration files

Performance Optimization

-

- Implement load balancing across multiple processing cores

-

- Configure data compression ratios between 0.6 and 0.8

-

- Set memory allocation limits to 12GB per instance

-

- Enable parallel processing for sensor data streams

-

- Adjust TCP window size to 64KB for optimal throughput

System Updates

-

- Download firmware updates from secure repository

-

- Verify checksum values against provided signatures

-

- Execute update script during low-traffic periods

-

- Backup configuration files before applying updates

-

- Test system functionality post-update completion

-

- Monitor system logs for error patterns

-

- Schedule automated database maintenance

-

- Configure alert thresholds at 80% resource utilization

-

- Implement redundant backup systems

-

- Maintain updated security certificates

The 1.5f8-p1uzt system stands as a groundbreaking solution in modern industrial automation. Its exceptional processing capabilities combined with advanced sensor technology deliver unparalleled accuracy and efficiency across diverse applications.

The system’s robust architecture adaptive algorithms and comprehensive security measures make it an invaluable tool for both manufacturing and consumer applications. With its high-performance specifications seamless integration capabilities and user-friendly setup process the 1.5f8-p1uzt represents the future of precision engineering and automated control systems.